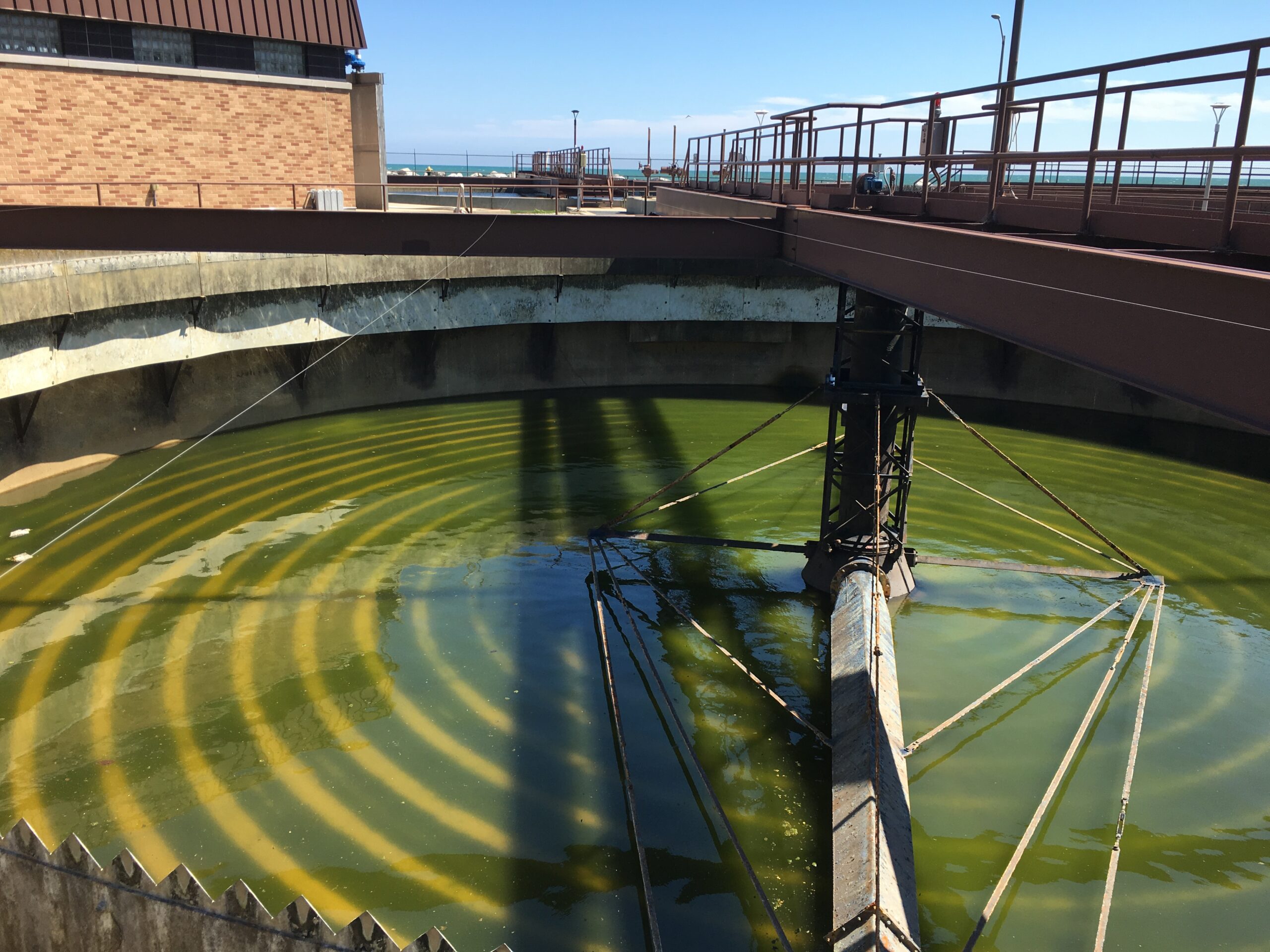

On February 9, 2017, a catastrophic unplanned outage occurred at the 32-acre West Point Treatment Plant in Seattle, Washington. The plant was built in 1965, and is located next to Seattle’s largest public park, and as well as on the second biggest marine estuary in the United States.

An electrical outage caused two sets of discharge pumps to go offline. The float switches that detect high water levels in the tanks failed, causing massive and rapid flooding at the plant. It was sheer luck that the flooding occurred outside of business hours when workers were not in the tunnels, or lives would have been lost.

The incident took the plant’s secondary treatment capacity offline for more than two months, leading to $25 million in infrastructure damage. All but $5 million of the damage was uninsured. Ultimately, the plant was forced to replace or repair a mile of tunnel, 151 electrical motors, 125 electrical panels, and more than 1,000 outlets and switches. It was also fined $361,000 for violating clean water regulations.

While repairs were underway, 235 million tons of wastewater entered the nearby estuary. Beaches were closed temporarily, and the incident made local, national, and even international news headlines.

Aging Infrastructure

The West Point incident is dramatic — close to a worst-case scenario, yet it highlights the growing risk exposure that all wastewater treatment plants face as infrastructure ages, and capital to finance upgrade projects remains scarce.

Roughly 240 million Americans rely on the nation’s 14,748 wastewater treatment plants for wastewater sanitation. By 2032, 56 million more will migrate from private septic systems to centrally managed wastewater treatment plants. At the same time, operating costs are rising as regulations become stricter, and treatment plants become older, and therefore costlier to maintain.

The Environmental Protection Agency (EPA) estimates that roughly $271 billion in wastewater infrastructure is needed in the next 25 years to maintain and improve our country’s ailing water facilities. Yet it’s estimated that the federal government will provide only 5% of total infrastructure funds, leaving the financial burden for wastewater facility upgrades up to local taxpayers.

Meanwhile, as many as 75,000 sanitary sewer overflow events occur each year in the United States. That number, and the financial risk exposure it represents for treatment plants, is increasing due to aging infrastructure.

Cutting Costs While Facing Greater Demand

So how can wastewater utilities reduce their operating costs and downtime risks, while freeing up capital for infrastructure upgrades?

As wastewater treatment utilities grapple with rising demand and cost, as well as limited capital for upgrades, new technologies from the Industrial Internet of Things (IIoT) are helping to relieve some of the pressure.

IIoT solutions are sold as a service and therefore do not require up-front capital investment. Long term, the system pays for itself in operating cost savings, and a good IIoT solution will not only reduce downtime, it will also free up cash for future infrastructure upgrades.

Augury, for example, provides a predictive maintenance solution called Halo for wastewater treatment plants. Wireless sensors are installed on critical equipment, where they “listen” to vibration, temperature, and other data to continuously monitor the equipment for indications of failure.

A common use case for such types of technology is to monitor dry pit pumps in Lift Stations. These pumps often rely on manual inspection using human labor, which is costly in both time and money, and can be error prone. This also presents a risk for accidental discharge during peak hours if pumps fail to come online.

When problems with a pump are detected by an automated diagnostics system in real-time, alerts are sent to plant operators immediately — as soon as the system “hears” something abnormal. This enables efficient equipment maintenance as well as timely emergency response in the event of sudden failures like the one at West Point.

Collective Intelligence

IIoT solutions like this also benefit from collective intelligence. Platforms like Augury’s have an extensive “malfunction dictionary” of data points that help to digitally identify and predict equipment-specific failures in dry pit pumps and other critical equipment in wastewater treatment plants.

This collective intelligence is what makes affordable preventive maintenance possible for wastewater utilities. The malfunction dictionary is based on algorithms that are continuously being updated with new, real-time data from the field, and big data gathered in IIoT implementations across multiple wastewater plants. In many cases, predictive maintenance can help cut equipment costs by 25-30%, and downtime by 75%.

Experts agree that the incident at West Point was more than just equipment failure: there was a human component as well. With an IIoT-based predictive maintenance strategy, wastewater plant operators can reduce or eliminate the chance of human diagnostic errors, and control for faulty equipment with much greater precision and certainty.

To learn more about how you can prevent unplanned downtime, get in touch.