Machine Health Rising

Manufacturing is currently undergoing a new Industrial Revolution driven by technologies such as IoT and AI. We are in the early stages of insight-driven manufacturing, where manufacturers use automated insights from technologies like Machine Learning to make better decisions across the operation.

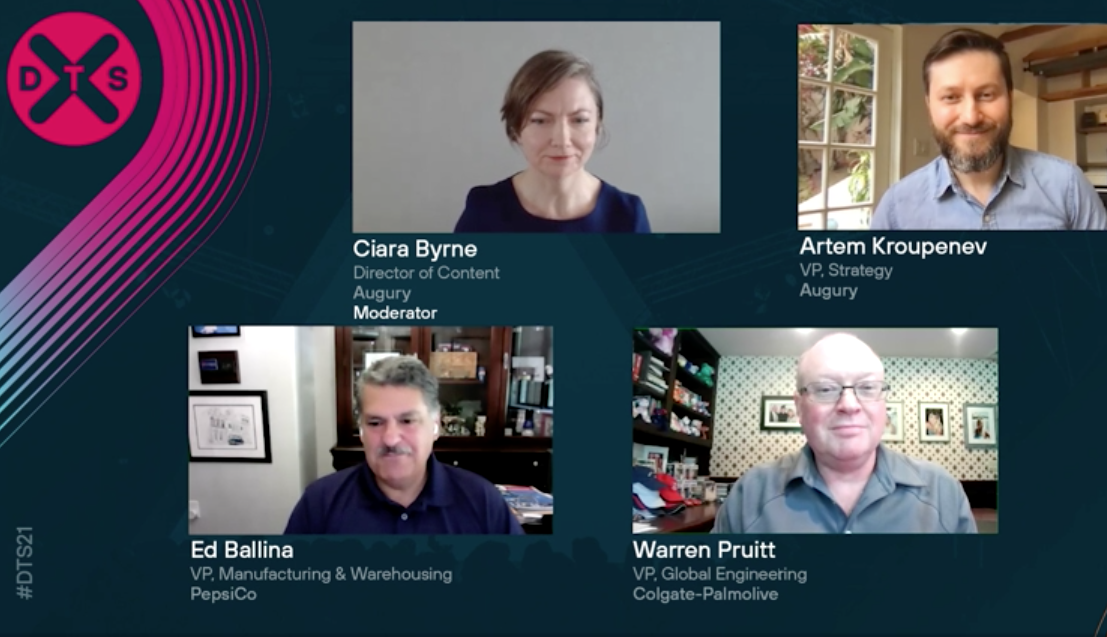

To address the sweeping changes ahead, Augury organized the panel ‘The Next Industrial Revolution: Era of AI, IoT and Machine Learning’. It took place this past June at the Dublin Tech Summit 2021.

Featuring 5,000 delegates and 100+ speakers, Europe’s fastest-growing tech conference brings together the most influential business and tech leaders from across the globe.

Experts On Manufacturing’s Digital Transformation

Moderated by Augury’s Director of Content, Ciara Byrne, the panel was quick to deep dive into the current challenges facing manufacturers. Everyone agrees: instilling agility and flexibility is the only way forward.

The expert insiders also have insights into how digital transformation is playing out differently in manufacturing than in other industries. They also offer advice on how to jumpstart long-term workforce transformation.

Turning Data Into Actionable Information

“With layers and layers of data, we need to learn to extract the right information,” says Warren Pruitt, VP of Global Engineering Services at Colgate-Palmolive. He also noted his company’s digitalization process was sped up by three years in response to the Covid-19 pandemic.

Based on immediate benefits, Colgate-Palmolive is now scaling their machine health program. However, the company also recognizes the need to link this with an equally robust change management program.

Maximizing Flexibility and Agility

“The operators are no longer part of the machinery. Now, there’s a platform doing all the ‘listening’ and gathering of data,” observes Ed Ballina, former VP of Manufacturing and Warehousing at PepsiCo.

“So, people need to be retrained for higher-value work. They need to become less of a technician and more of a translator of data. In this way the work becomes more satisfying – as it goes from being reactive to proactive.”

Syncing Operations and Outcomes

“Through all these new insights and the hybridization of roles, we can then actually bring operations and business outcomes in sync,” says Artem Kroupenev, VP of Strategy at Augury.

With as a result: better quality at less cost. Everyone wins.