When a manufacturing plant’s sole exhaust fan malfunctions, technicians must act fast to avoid a halt in production. This Win-of-the-Week shows how Augury detected a vibration anomaly just days after being installed on a critical exhaust fan and then worked with the customer to rapidly resolve the issue, preventing expensive structural damage and production delays.

Industry – Building Materials //

Machine – Exhaust Fan //

Fault Type – Resonance Condition //

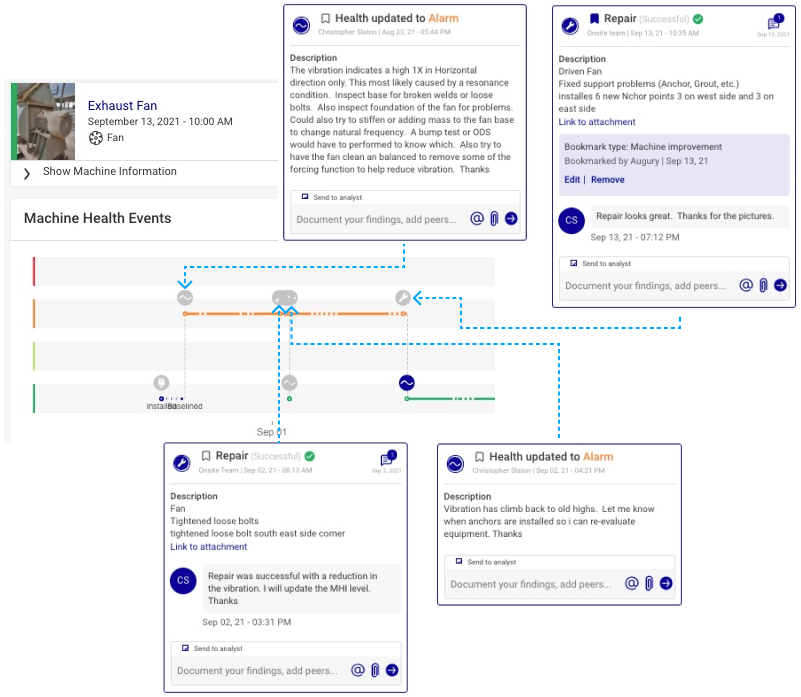

Image 1:

Machine Health status, alerts, and communications between Augury vibration analysts and the onsite team are tracked and logged in the Augury platform as issues are detected and addressed.

Within two days of connecting the dry mix plant’s only exhaust fan to the platform, Augury’s AI detected changes in the velocity RMS. The data was two to three times higher in the horizontal direction compared to the vertical direction, signifying a resonance issue on the machine. Augury’s vibration analyst put the machine into Alarm, alerted the customer, and recommended inspecting the base for broken welds or loose bolts.

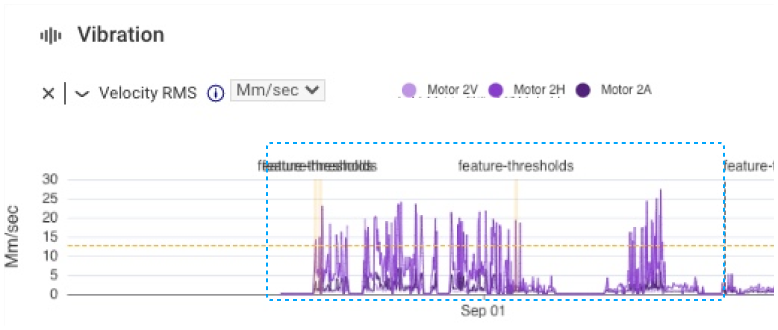

Image 2:

Augury’s algorithms analyze over 840 unique feature sets. Changes in Vibration Velocity RMS at time of the alerts and following repairs are shown below.

Although onsite technicians tightened the four bolts that secured the base to the concrete floor, the vibration levels increased again three hours later. The vibration analyst notified the customer that the machine likely had a soft foot or looseness condition. The onsite team leveraged this immediate feedback from Augury to troubleshoot, deciding to better secure the base by installing six new anchor points and new grout to prevent the issue from recurring. After these repairs, vibration decreased to normal levels, and the machine health status was updated to Acceptable.

Image 3

The exhaust fan’s new anchor point configuration as indicated by the arrows.

Had this manufacturer not installed Augury two days earlier, they may not have noticed the critical exhaust fan’s resonance issue until the base had twisted and damaged the structure, leading to substantial ductwork and pipe issues. The excessive vibration could have also loosened other components, all leading to halting the entire production line.

The Augury solution and expert team helped the customer avoid expensive repairs and costly unplanned downtime by detecting the resonance issue early and collaborating with the onsite team to properly address it right away.

Want to learn more? Just reach out and contact us!