Comprehensive

Asset Coverage

We cover all tiers of criticality and all types of rotating assets across many industries

Discover how you can predict and prevent machine failures and drive down maintenance costs using the Internet of Things (IoT), Artificial Intelligence (AI), and reliability expertise.

Improving machine performance and plant efficiency while battling unplanned downtime and high MRO costs- the work for maintenance and reliability teams never stops. But with real-time visibility into your equipment and prescriptive insights in your hands, you can run your production lines like never before.

Solve your toughest maintenance and reliability problems. See impact across your enterprise- from the plant floor to the C-Suite.

Developed for maintenance and reliability teams by maintenance and reliability professionals, Machine Health provides the technology and resources you need to prevent machine failures and improve overall efficiency.

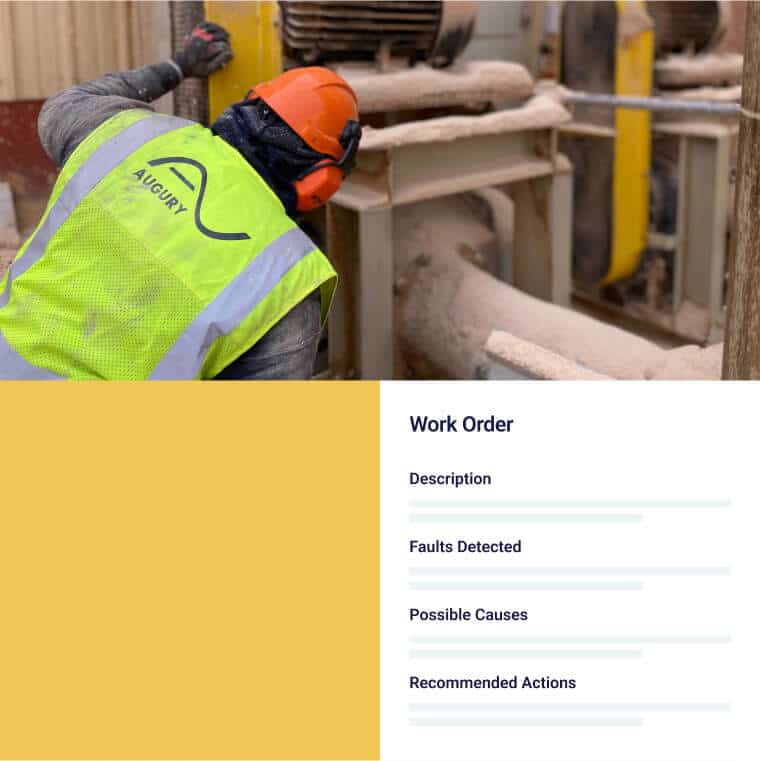

Sensors capture and transmit data to Augury’s platform 24/7

AI detects issues, explains what caused them, and prescribes courses of action

Augury’s platform, AI insights, and expert support enables users to prioritize and plan

Users collaborate and act on guidance to improve the health and performance of their machines and processes

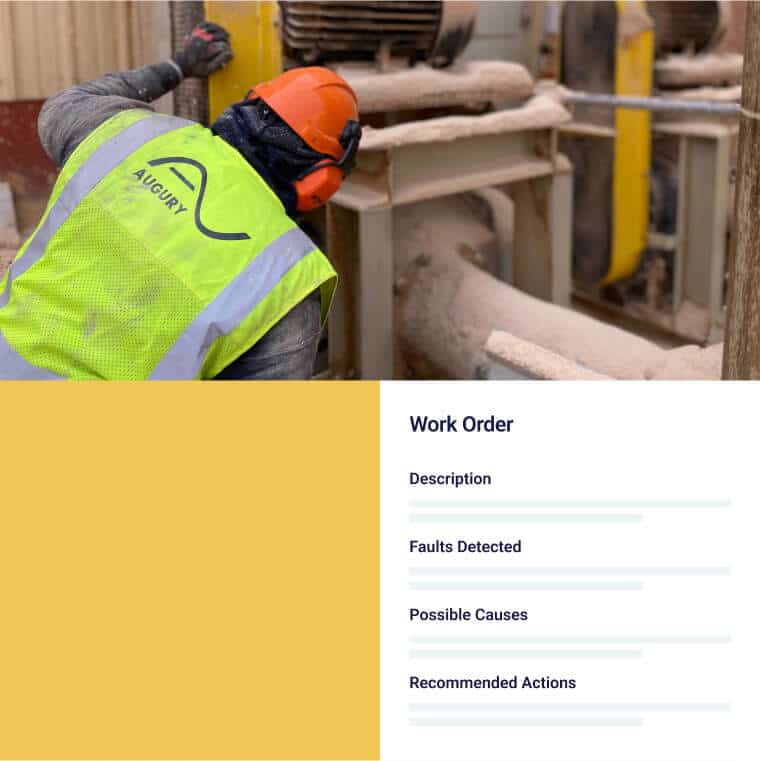

Sensors capture and transmit data to Augury’s platform 24/7

AI detects issues, explains what caused them, and prescribes courses of action

Augury’s platform, AI insights, and expert support enables users to prioritize and plan

Users collaborate and act on guidance to improve the health and performance of their machines and processes

Machine Health for Dummies can help you kickstart a new era of reliability to get prescriptive maintenance right and transform the way you work.

We cover all tiers of criticality and all types of rotating assets across many industries

Immediate diagnostics that are so accurate and actionable, they’re backed by an insurance guarantee

User-built and easy adoption sets a new standard for how maintenance and reliability teams work, every time

We support enterprises at a global scale with an experienced services team.