Timely machine insights and close partnership results in enormous cost avoidance:

Industry – Pharmaceuticals

Machine – GMP Air Handling Unit (AHU)

Fault Type – Mechanical looseness

Outcome – Saved an estimated $9M-$13M in downtime, maintenance, and cleaning costs (not including lost productivity and profits from unmanufactured medicine).

Equipment failure in the pharmaceutical industry poses a wide range of financial risks–a single issue could cost anywhere between a few thousand dollars or millions of dollars, on top of interrupting the production of lifesaving medicines.

This particular “perfect storm” was avoided because a proactive maintenance team was able to act on continuous monitoring data, advanced AI, and expert reliability communication and guidance to discover and repair a problem with a vital air handling unit. Had it gone unresolved, the catastrophic failure would have cost this leading pharmaceutical manufacturer over $9 million in downtime, maintenance, and mandated clean-up costs.

The episode demonstrates the possibilities of a deep partnership with Augury and lessons from the experience have helped improve production and maintenance standards at the facilities. These best practices include mitigating the risks of over maintaining machines and the shortcomings of route-based inspections, as well as the positive impact continuous monitoring can have and the value of Augury expertise. This event and others continue to positively impact the company and the success of the team’s digital initiatives have attracted the attention of their global leadership.

Image 1:

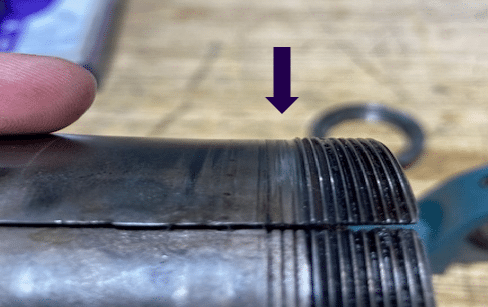

The customer logs this event to their aggregated Success and Impact Dashboard for 2023..

A Mysterious Machine Problem

Augury began partnering with this global manufacturer of pharmaceutical products in 2019. Less than a year later, the company had installed Machine Health continuous monitoring sensors on over 500 critical pieces of equipment across multiple sites and buildings. From 2019 to 2023, the company saw meaningful results with their program. The most notable event happened in January 2023 when vibration levels on a vital GMP air handling unit began to rise. Due to these heightened levels, the machine was moved into “alarm” mode and the maintenance team alerted about the escalation. Noting that it was typical to keep fans like this running for a year or more without inspection, the on-site maintenance team made a strategic decision to keep the machine running and continue monitoring.

Less than four weeks later, Augury re-issued the alarm. Seeing vibration levels continue to rise, the Augury Reliability Team suspected motor imbalance, possibly from a bearing issue, and recommended inspection for buildup or erosion.

Image 2:

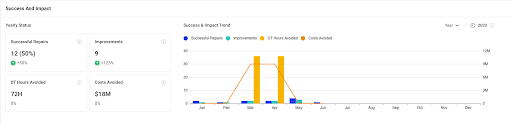

Augury’s AI at work captured anomalies related to increasing vibration levels – Velocity RMS, Acceleration P2P, and Envelope RMS – followed by return to normal levels after the repair

Solving the Problem

Days later, the machine problem was moved to “danger” due to increased axial vibration. During discussions between Augury’s reliability experts and the company’s maintenance team, it was discovered that the issue stemmed from scheduled preventative maintenance (PM) where the major system components were replaced two months prior. This helped surface systemic issues related to over-maintenance, which introduces unnecessary risk.

Working with data from thousands of clean air supply fans, the combination of Augury’s AI insights, ondemand expertise, and consistent communication provided a detailed diagnosis: the number 4 bearing had come loose following the PM session, which had in turn caused a misalignment in the belt sheaves and vibration exacerbated by the motor mount design. Empowered with this actionable information, the maintenance team made plans for a machine shutdown.

A One-Hour Window for Action

Pharmaceutical air-quality regulations stipulate that an interruption of the fan system that lasts longer than 60 minutes requires an extended shutdown and detailed, thorough cleaning of the area supplied by this air handling unit. In this particular case, a shutdown would have cost the company between $9M-$13M in downtime, maintenance, and cleaning costs–a range which doesn’t even include lost productivity and profits from unmanufactured medicine.

The maintenance team was able to complete the repair in 57 minutes–just inside the regularly mandated window of 60 minutes, avoiding an extremely costly shutdown. Without the analytics, insight, and guidance given to them by Augury’s Machine Health, this likely wouldn’t have been possible.

Images 3a and 3b:

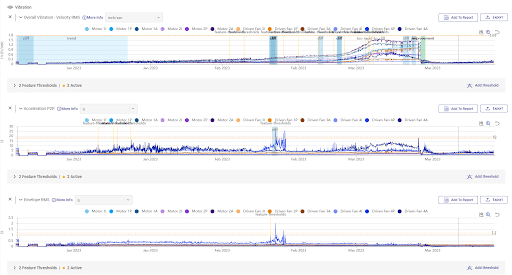

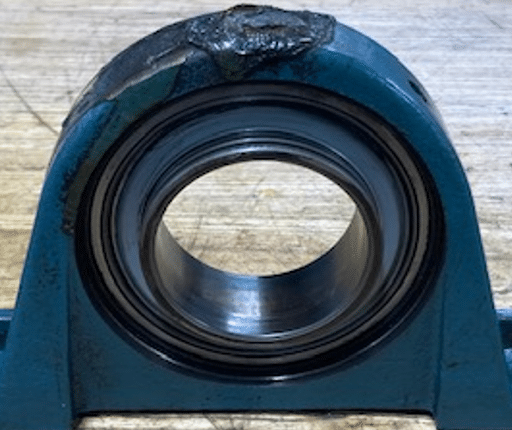

Physical failure analysis supports the data observed and the direction given to the customer by Augury’s Reliability Team. Scoring/discoloration of the shaft sleeve and bearing inner race demonstrate that there was looseness and relative motion between the components.

Image 3a:

Damaged fan bearing due to improper installation

Image 3b:

Wear on bearing sleeve indicating looseness due to improper installation