Recent research shows how AI-driven Machine Health systems are at least 20 percent more accurate than legacy alternatives – while also avoiding between 40 and 70 percent of false alerts.

Almost every aspect of our lives today is impacted by artificial intelligence: web searches, e-commerce, health, computer vision, driving, navigation, logistics, the services we consume, financial markets, and even the pictures we take with our smartphones. Why? Because it works. We find what we need more quickly, and the pictures we take are prettier.

State-Of-The-Art Versus State-Of-Before

At Augury, we dealt with AI focused on perfecting the health, availability and performance of large production lines. With a 99% accuracy rate, we are able to save our customers millions of dollars – thanks to our ability to eliminate unexpected production downtime and dramatically reduce repairs costs. And we wouldn’t be able to do this without developing powerful AI algorithms.

Obviously, before deploying Augury’s AI, many of our customers used other ways to minimize unplanned downtime and production losses. And as data enthusiasts, we began wondering if we could calculate the actual additional value of using AI compared to more traditional approaches.

Real Alerts Versus False Alerts

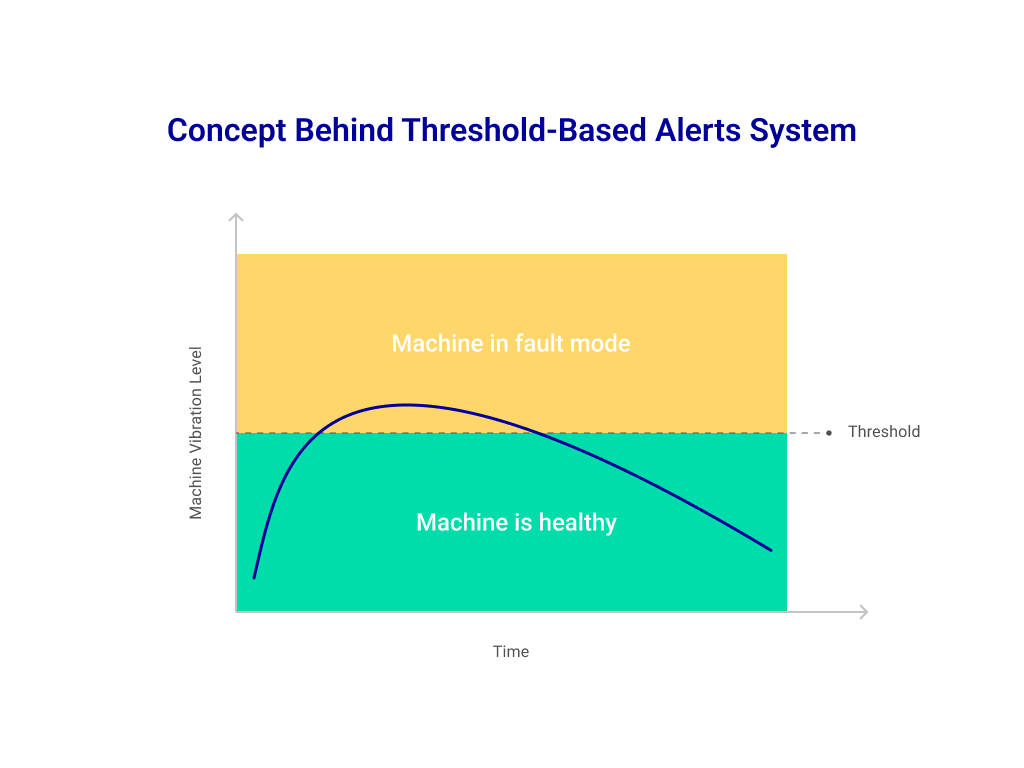

One such legacy approach is “threshold-based analysis”, which Augury actually uses in some of the measurements we take related to machine vibrations. With threshold-based analysis, an alert would be triggered once a machine’s overall vibration level reached a certain level. Then, ideally, a vibration expert would analyze the data and try to figure out the source of the alert. This differs with Augury’s AI in that we are continuously analyzing the machine’s vibration spectrums with and without regards to the overall vibration levels.

In a threshold-based analysis, there is one crucial decision: Where to set the alert threshold? The higher the threshold is, the more likely it is that a critical production machine will fail unexpectedly. On the other hand, the lower the threshold is, the more false-alerts will be received.

The Experiment

The most common way to determine the threshold level is by using the ISO standard for vibration threshold (e.g., ISO-10816 or equivalent). However, in many cases, users chose to adapt the threshold levels according to their specific needs.

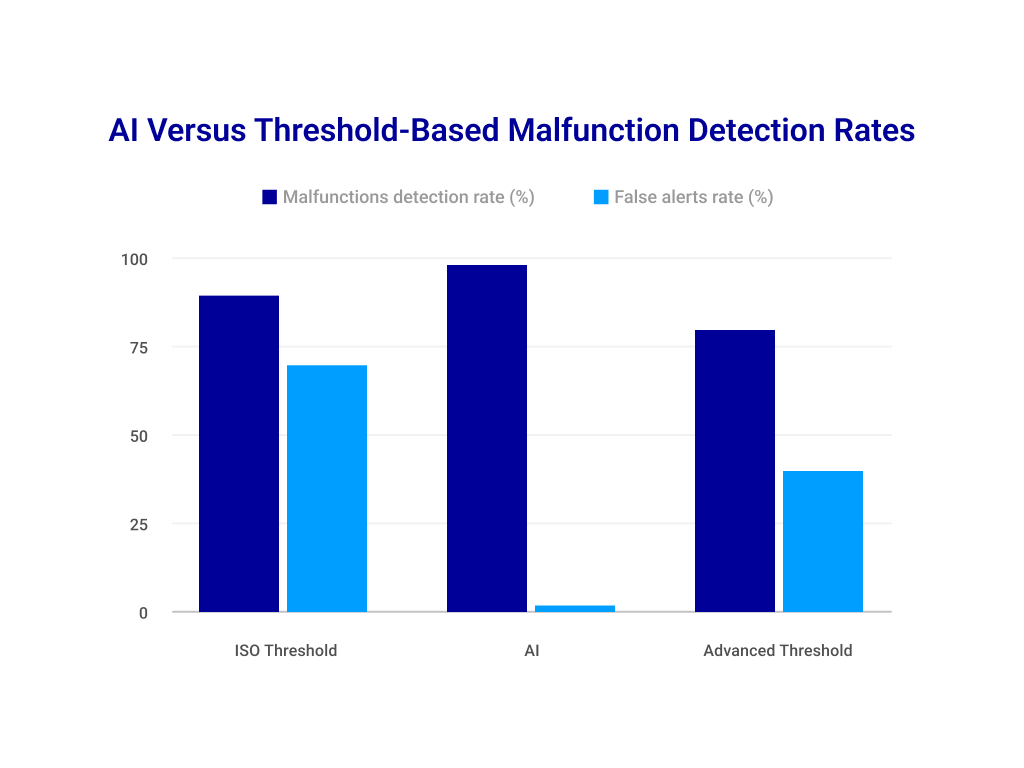

With our research, we decided to compare Augury’s AI to both ISO thresholds and custom thresholds. Led by Daniel Barsky and Nadav Dishon from Augury’s algorithms and data teams, the study was performed on over 29,000 event detections coming from over 90,000 critical machines monitored by Augury globally over a period of six months.

And while we witness the benefits of Augury’s AI during our day-to-day interaction with our customers, we were still astonished by the results.

The Numbers Don’t Lie

Out of the 99% verified AI malfunctions detected, the ISO threshold system “caught” 90% of the malfunctions. This sounds great until you discover the ISO system also “caught” an additional 70% false-alert malfunctions. This means that if a production facility was to use the ISO threshold system, the facility’s maintenance team would have spent 70% of their time chasing after malfunctions that do not exist. Needless to say, the facility’s team would quickly lose confidence with such a system and ignore all further alerts.

For this very reason, most users prefer to set-up their own thresholds in the hopes of reducing the number of false alerts. So, we compared Augury’s AI with an advanced threshold approach. The results were indeed better in the term of false alerts: there were now “only” 40% false alerts. But this came at a cost since now only 80% of the faults were detected. And again, with a maintenance team spending 40% of its time chasing non-existent malfunctions, all confidence would be soon lost with such a monitoring system.

The Hidden Benefits Of Continuous Improvement

And when we started crunching more numbers, we also discovered that by detecting 20% more problems, you in fact increase savings and ROI by 30%. This is because applying AI also has other trickle-down advantages besides increased accuracy and decreased false alerts. It can also have other benefits in terms of safety, scalability and saving human time that can be used for more proactive activities.

So, in short, thanks to on-going technological advancements, AI is becoming available in more and more aspects of our lives. It’s certainly helping humanity in the way we can more efficiently manufacture our food & beverages, medicine, energy and much more.

And in further good news: our efforts have only just begun.

Read The White Paper ‘The Power of Augury’s AI’. Or to learn more about how our AI is making the jobs of manufacturers easier, get in touch today.