Until recently, supply chain reliability was the worry of supply chain people. But in a post-COVID-19 world, they’re no longer alone. Everyone worries about their favorite products making it to the shelf. At Colgate-Palmolive, we’ve been bolstering our supply chain reliability by moving toward predictive maintenance of our machinery — a model that preserves “machine health” through 24/7 monitoring via wireless sensors combined with analytics powered by artificial intelligence [AI].

*This article first appeared on Linkedin.

By Warren Pruitt, Vice President – Global Engineering Services at Colgate-Palmolive

Until recently, supply chain reliability was the worry of supply chain people. But in a post-COVID-19 world, they’re no longer alone. Everyone worries about their favorite products making it to the shelf. At Colgate-Palmolive, we’ve been bolstering our supply chain reliability by moving toward predictive maintenance of our machinery — a model that preserves “machine health” through 24/7 monitoring via wireless sensors combined with analytics powered by artificial intelligence [AI].

Unlike preventative maintenance [scheduled routine check-ups for equipment] this digitally enabled method diagnoses problems early, allowing for quick remediation and minimized downtime. It’s analogous to always wearing a glucose monitor or EKG rather than waiting until your annual doctor’s visit to discover something’s amiss.

Even better, the data fed from our machines to our partner Augury’s software platform gets compared to their learnings from over 80,000 other machines operating around the world. That massive analytical scale brings us insights on how to optimize the performance of equipment and make ever-smarter choices on how and where we deploy it. What’s possible only gets more compelling as this AI solution harnesses more data to create better “health outcomes” for our machines and our business.

Finding the Right Solution

This conversion process started a few years back as we searched for a robust way to do predictive maintenance. Like Goldilocks, it took some trial and error to find the “just right” solution.

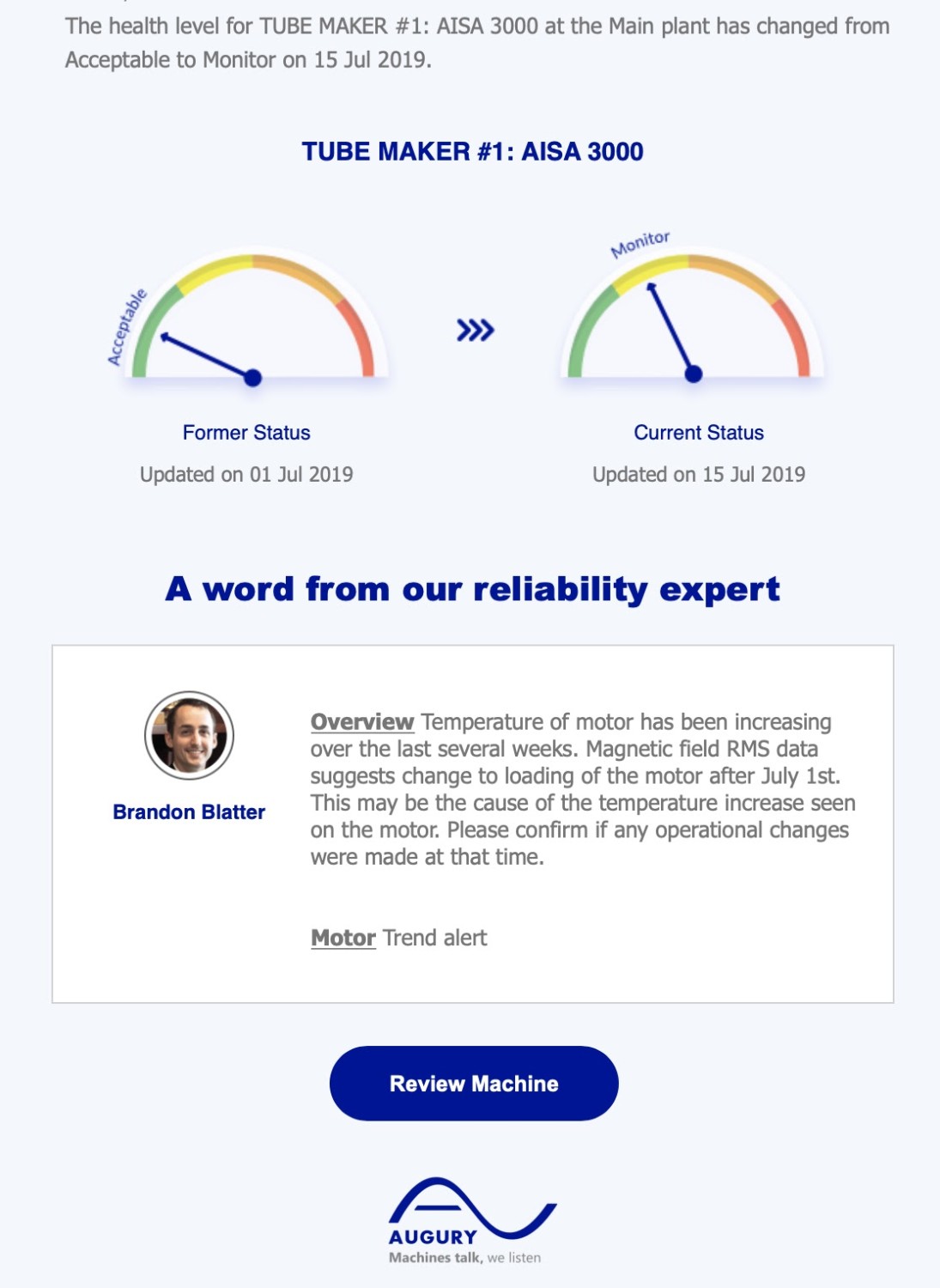

Bluetooth sensors needed a person with a smart phone to collect the data. Wired sensors came with a high price tag. But the wireless-sensor solution we’re now using automates that data collection and analysis — monitoring vibration, magnetic flux (energy use) and surface temperature. When issues arise, reliability professionals remotely alert and collaborate with our plant teams as needed.

Although early diagnosis of problems is a key advantage here, there are additional savings from extending use of equipment past what would be typical preventative maintenance schedules. Instead of stopping production as a matter of course, say, every six months, we monitor the near real-time health and performance of our machines and if all is well, we can safely keep them running nine months or longer. This has increased our available manufacturing capacity, allowing higher production volumes, which has been invaluable during the COVID-19 crisis.

Evident Savings

Since implementing this technology at several of our manufacturing facilities, Colgate has already seen significant savings of time, money and energy.

For example, the AI detected rising temperatures in the drive motor of one of our tube makers and alerted the plant team. Upon inspection, they discovered a problem with the motor’s water cooling system. By getting it quickly resolved, we prevented the drive from failing due to overheating, which would’ve stopped the tube production line and incurred replacement costs. We figure the savings at 192 hours of downtime and an output of 2.8M tubes of toothpaste, plus $12,000 for a new motor and $27,000 in variable conversion costs.

In another case, the AI provided an early warning that a gearbox in a liquids machine was experiencing structural and operational issues, putting it at high risk of failure that could shut down the line. The team was able to order a replacement gearbox and plan the maintenance to swap it in, bringing the machine to acceptable condition with minimal interruption.

Looking Ahead

The benefits of having real-time access to machine health analytics have been so powerful, we’re going to roll out this technology across our global supply chain. Augury recently helped guide our installation of their technology remotely using augmented reality.

We’re excited to be early adopters and enthusiasts and hope our manufacturing peers join this movement toward digitization and predictive maintenance. The more data we have to learn from, the better results we will enjoy. Which can only mean more reliable availability of products. And that’s a future we can all smile about.

Learn more about the collaboration between Augury and Colgate-Palmolive.