While still an essential metric for manufacturers, Overall Equipment Effectiveness (OEE) is limited in its ability to take in the ‘big picture’. Now, AI can be applied to also measuring Overall Line Efficiency (OLE) for a fuller view of the whole manufacturing process – backed by actionable insights.

Overall Equipment Effectiveness (OEE) is a widely accepted and utilized manufacturing evaluation method. However, Industry 4.0 is raising the standards of production, and OEE is limited in its ability to take into account more complex systems.

To respond to this need for a better-suited metric, a technique known as Overall Line Efficiency (OLE) is being used. It is much better equipped to describe multiple production lines and the interaction of a number of various sub-processes within a larger production process.

Ideally, a complete performance evaluation approach will incorporate both OEE and OLE methods with appropriate modifications to suit the operation.

Efficiency Vs. Effectiveness

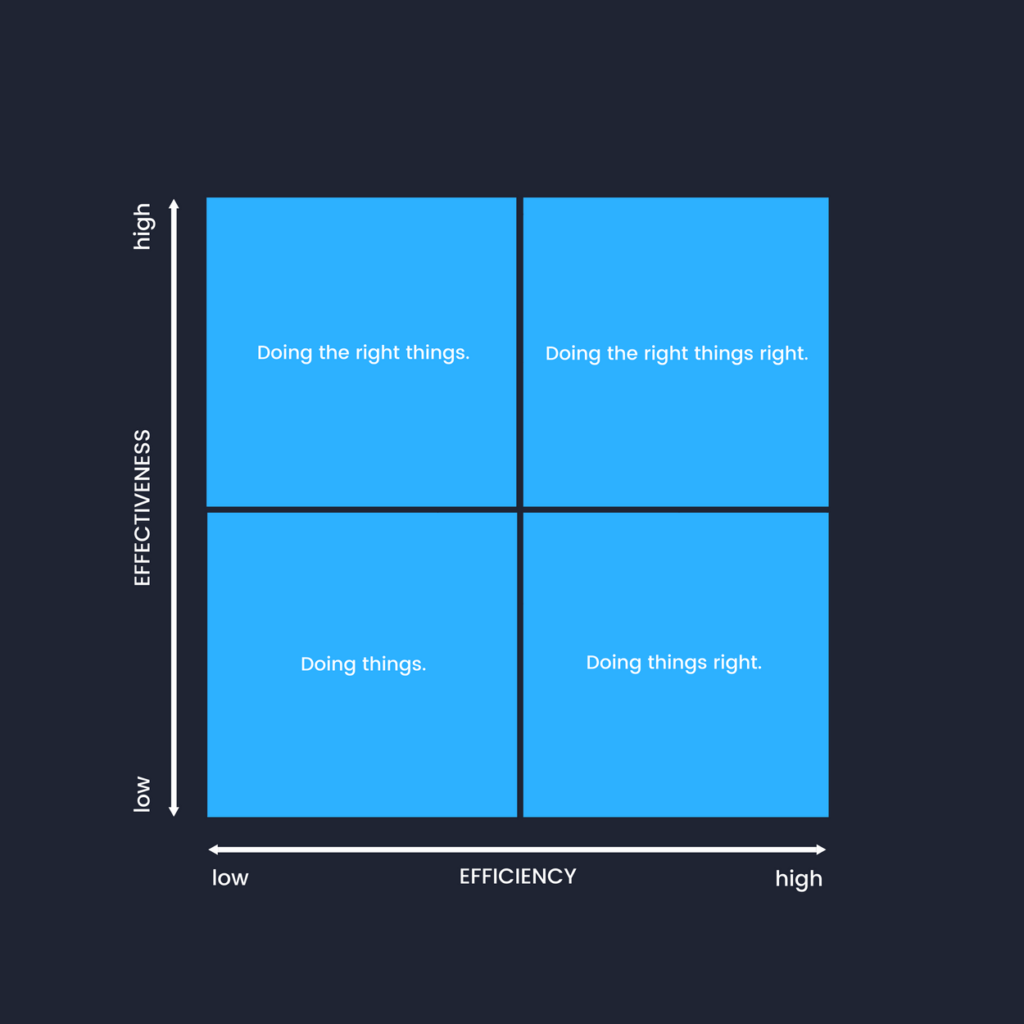

To differentiate between OEE and OLE, it helps to start by clarifying the difference between effectiveness (in OEE) and efficiency (in OLE), two terms often misused in the context of manufacturing.

The simple diagram above demonstrates that effectiveness focuses on performing the right tasks and aiming for the right goals, while efficiency is about performing tasks in an optimal way.

Overall Equipment Effectiveness (OEE)

Overall Equipment Effectiveness is a fundamental KPI that is used to improve manufacturing processes by using benchmarking and analysis to pinpoint inefficiencies and to categorize them.

OEE seeks to describe the overall utilization of materials, equipment, and time in a production process. It is calculated according to the below equation, although there are a number of ways of defining the 3 contributing parameters…

OEE = Availability X Performance X Quality

For production lines consisting of a number of unbalanced (unpaced) machines, OEE is not ideal since it’s better suited to evaluate individual assets.

Overall Line Efficiency (OLE)

Overall Line Efficiency is a relatively new metric in manufacturing and builds off of OEE to compare the current performance of a production line with how well it could be performing.

OLE also takes into account the personnel involved in the various processes. In this way, OLE seeks to optimize the synchronization between the output rates of machines and the use of human resources.

OLE = OEE of Machine A + OEE of Machine B + OEE of Machine C

3

The above calculation assumes that the importance of Machine A, B, and C are the same – i.e. have the same “weight”. In most manufacturing scenarios this will not be the case, with different processing stages having different weights, resulting in a more complex OLE calculation.

Overall Line Efficiency can be expanded further to include a calculation for each production line (taking into account the bottleneck for each), and to formulate a calculation that incorporates a number of production lines.

New Methods for Calculating OEE and OLE

The use of artificial intelligence is steadily growing within the manufacturing sector and can be applied to both OEE and OLE calculation. AI’s advantage here is its ability to adapt to different manufacturing scenarios thanks to the algorithms’ flexibility.

In other words, an AI algorithm used to calculate OLE isn’t affected by whether the operation is in the aerospace or food processing sector. Any meaningful differences between those sectors can be reflected in the algorithm by setting specific weight values for critical parameters.

Using Artificial Neural Networks For Overall Line Efficiency

Artificial Neural Networks (ANNs) can easily handle the complexity of OLE calculations, and lead to far more accurate results than those achievable through more traditional calculation methods.

Implementing ANNs to calculate Overall Line Efficiency is not an immediate process – the algorithm needs to be trained. This is done by feeding the ANN existing historical data categorized as input (OEE) or output (OLE) along with other relevant data from the machines and production floor. ANNs can also be fed data from observations made by operators, and thereby enhancing the training through additional information layers.

Ideally, a complete performance evaluation approach will incorporate both OEE and OLE methods with appropriate modifications to suit the operation.

Better Manufacturing Management with Overall Line Efficiency

Using a combination of OEE and OLE calculations to monitor the performance of a manufacturing operation can be extremely useful for management. Due to the high number of variables involved, artificial intelligence in the form of Artificial Neural Networks and other techniques, is very well suited to this field and can offer actionable insights for better management decisions and greater impact.

Also read: ‘How to Improve OEE in Industry 4.0‘. Or reach out direct to find out more about how you can apply OLE for your own particular production lines.