A leading beverage producer deployed Augury at a relatively new plant to support their skilled but understaffed in-house maintenance team and enable them to scale. They were counting on Augury to detect machine issues early, giving them time to order parts and plan repairs before machines failed. But Augury surprised them right away, identifying an unexpected issue straight out of baseline on a practically brand new process pump.

Industry – Beverage //

Machine – Process pump //

Fault Type – Motor bearing wear //

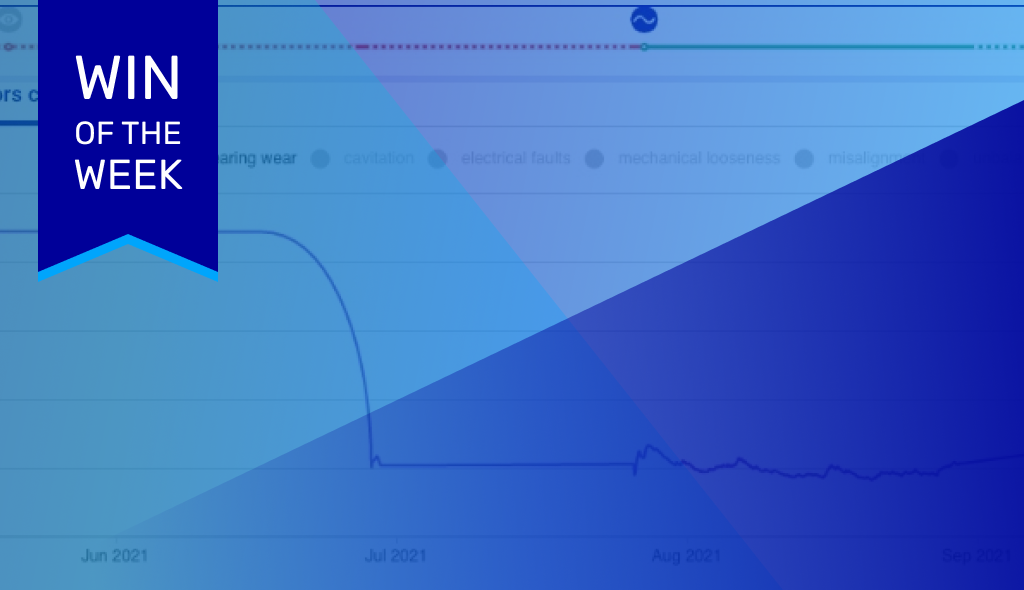

Image 1:

Machine Health status and alerts are tracked, logged, and visible to the Augury vibration analyst and on-site teams in the Augury platform as issues are detected and addressed

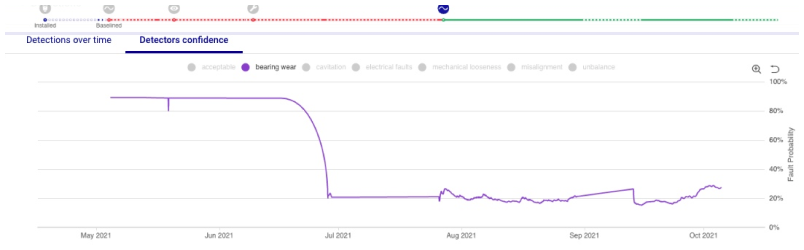

Image 2:

Augury’s algorithms analyze over 840 unique feature sets. Changes in Vibration Velocity RMS and Acceleration P2P at time of the alert are shown below.

With the very first live data transmitted from the sensor after installation and baseline, Augury’s algorithms detected extremely high acceleration levels on a critical process cooling water pump, indicating motor bearing wear Even though the customer had not yet assigned unique product numbers for the bearings to help Augury pinpoint the exact location of the fault, the detectors confidence level for bearing wear somewhere on the pump was near 90%. The vibration analyst placed the machine in Danger and recommended replacing the bearings as soon as feasible.

Since the plant had redundancy, they could quickly take the affected machine offline, replace the bearings, record the bearing numbers in the Augury platform, then bring the system back online. Immediately after the motor drive end bearing was repaired, acceleration peak to peak improved tremendously, down to only 1.5 g from over 25 g (five to six times what’s considered an early bearing wear situation). The machine status was changed to Acceptable.

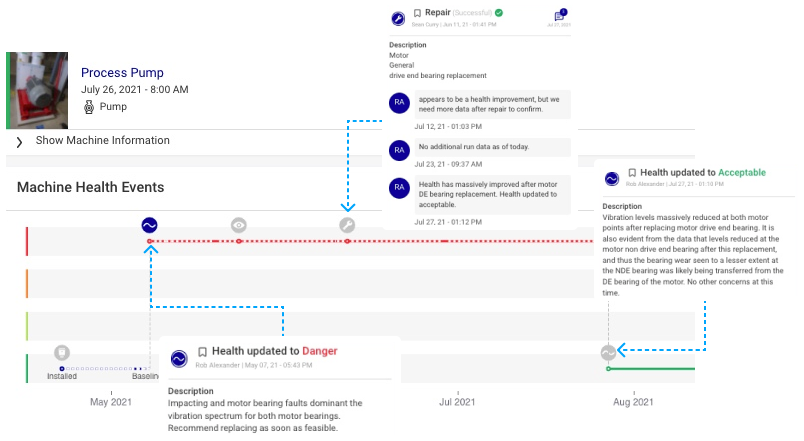

Image 3:

Augury measures confidence as the algorithm’s level of certainty that there’s an issue. Changes in the detectors confidence in bearing wear before and after the bearing replacements are shown below.

This baseline win – on a relatively new machine – prevented catastrophic machine failure, eliminated potential fire danger, and avoided costly repairs and lost production time. Augury’s algorithms detected the severe bearing wear from the very first data set, even without the bearing numbers. Receiving the product numbers for the replacement bearings further validated the accuracy of Augury’s diagnosis and confirmed the effectiveness of the repair.

Want to learn more? Just reach out and contact us!