Some supporting machines are less critical to a manufacturer’s operations, but still contribute to potential downtime and incur extensive amounts of M&R resources due to the number of assets. This Win of the Week demonstrates the value of a new solution in Augury’s portfolio, Machine Health for Supporting Equipment (MH SE). MH SE sends predictive AI detections directly to users to enable cost-effective and data-driven maintenance planning across the next tier of industrial rotating equipment.

Industry – Pet Food //

Machine – Fan Circulator for Oven //

Fault Type – Bearing Wear //

Success at scale with Augury’s Machine Health for Critical Equipment solution (MH CR) prompted a leading pet food manufacturer to participate in an early deployment of MH SE – where Augury’s system identified bearing wear in an oven fan with a high degree of confidence. This led the onsite team to replace the fan’s bearings.

Image 1:

Augury’s AI detected vibration anomalies on the fan and directly alerted the customer. Pictured below are the increases in Vibration Acceleration P2P (Vibration Acceleration Peak to Peak captures the strongest forces impacting machine vibration often related to component impacting or worn gears) and Envelope RMS (Envelope Root Mean Squared represents the energy or power in the vibrations, typically signalling the severity of the fault detected). Augury’s algorithms analyze over 849 unique feature sets.

On the right, AI detections are visible to the on-site team in the Augury platform where users provide feedback on the detection and log repairs when issues are addressed, creating a record for the asset.

Shortly after installing Augury’s MH SE across the majority of the site’s supporting equipment, Augury’s AI detected and directly alerted the onsite team about developing faults within an oven’s circulator fan. The team was able to clearly see increases in the overall vibration metrics as the MH SE page highlights for users what trends are related to each AI detection and precisely when the cliff detection was triggered. (Cliff detections occur when anomalous data trends persist at a specific level over a consistent period of time.)

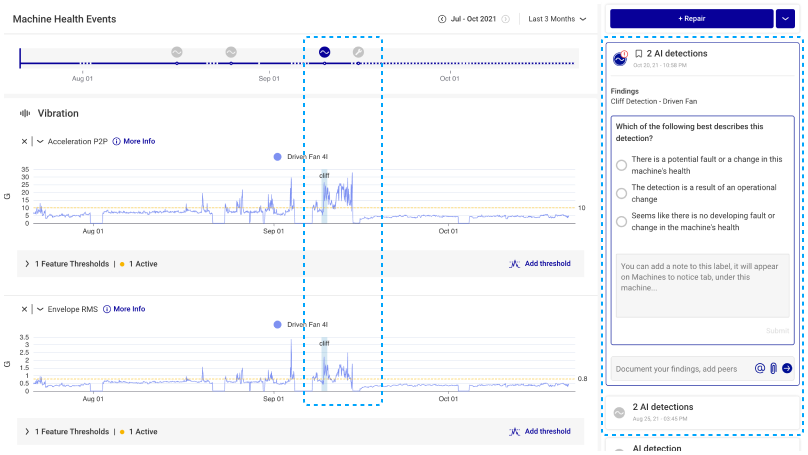

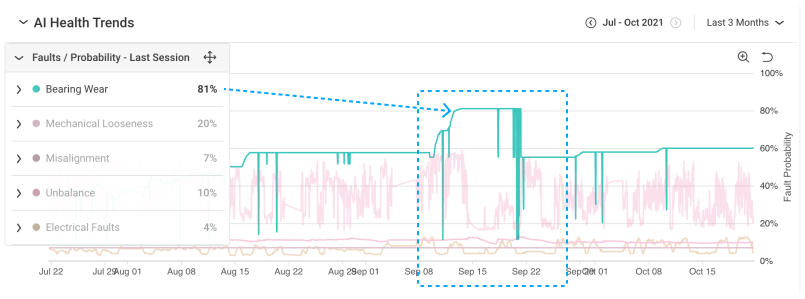

Image 2:

Detectors confidence level (fault probability) for bearing wear at 81% correlated to the increasing vibration levels above. Post-repair, vibration and detector confidence levels returned to normal, confirming the success of the repair.

In addition to surfacing key health trends, MH SE diagnostics include a confidence detector score. When the facility team further examined the data, they saw the most likely fault was bearing wear (81%). This prompted them to take action and repair the machine. The success of the repair was confirmed when the data returned to baseline levels. The platform also enabled the team to provide feedback about the AI detection and set a threshold to watch for future changes.

Augury’s MH SE solution works alongside MH CR to help manufacturers with a large fleet of assets and a limited number of technicians optimize their maintenance activity. Teams can now replace guesswork, waste, and unplanned downtime with cost savings, productivity, and increased autonomy.

Want to learn more? Just reach out and contact us!