Tariffs. No tariffs. Speed up production. Cut costs. Find a new supplier… We’re operating in an industry that’s changing day by day. Are you reacting fast enough on the plant floor? Probably not. You need a maintenance strategy that’s as flexible as the current business environment.

When market conditions get choppy and production schedules start looking like spaghetti charts, most maintenance teams find themselves in a bind. That’s because most maintenance strategies aren’t easy to modify when your plant load does.

If your team is still doing time-based maintenance, you’re likely either:

- Over maintaining assets that you rarely run

- Under maintaining equipment that’s been pulling double shifts for weeks

- Closing unexecuted work orders with a blindfold and a prayer

None of these result in good outcomes when parts, labor, and uptime are more valuable than ever.

When Budgets Follow Production, Time-Based Maintenance Fails You

Many plants tie their maintenance budgets to production output. If you’re producing less, your budget gets cut. If you’re running hot, maybe you get a little extra budget – if you’re lucky.

But when you’re using time-based maintenance, this becomes a budgeting nightmare. The calendar doesn’t care if your line was idle or running flat out. Your scheduled PMs still show up, and your planner has to figure out how to justify or defer them. A lot of these decisions are made quickly with incomplete data.

Maintenance managers are forced to either spend above budget to “keep up” with time based PMs, or cancel or delay them and hope nothing breaks.

Neither is ideal, and both increase the risk of unplanned downtime at exactly the wrong moment. Speaking from experience, it is not fun to answer the questions, “Don’t we have a maintenance plan for that failure? Why did it fail?”

“With a Machine Health platform, your maintenance plan won’t need a complete rewrite every time sales adjust their forecast. Your maintenance planner and scheduler will thank you profusely for this.”

Condition-Based Maintenance = Smarter, Calmer Planning

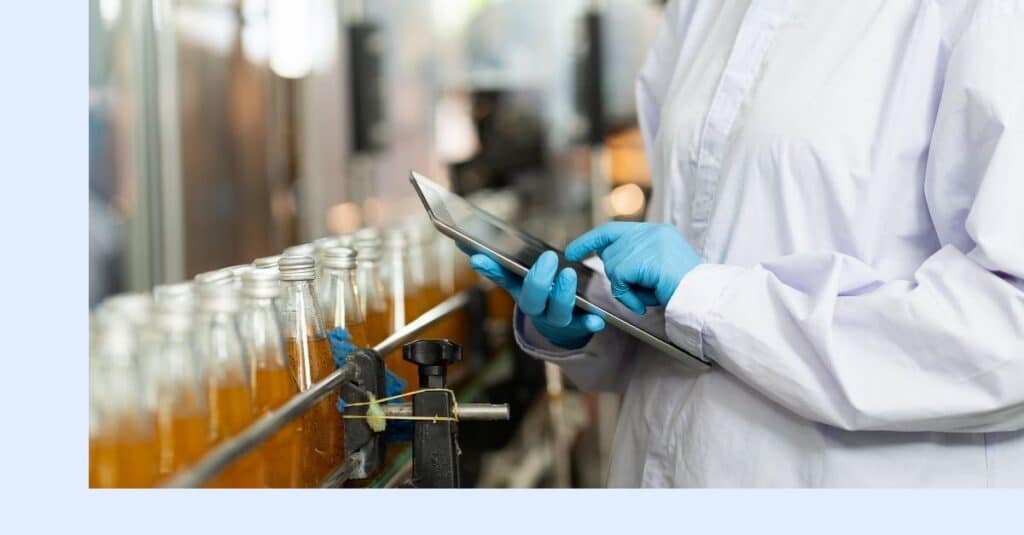

When you shift to a condition-based maintenance strategy it means your maintenance decisions are driven by the actual condition of the equipment, not just a date on a calendar.

Platforms like Machine Health make this transition easier than ever. By monitoring vibration, temperature, and other key indicators, they can tell you when something actually needs attention, independent of your production schedule.

This means your maintenance plan won’t need a complete rewrite every time sales adjust their forecast. Your maintenance planner and scheduler will thank you profusely for this.

Risk-Based Maintenance Decisions, Powered by Reality

Condition-based programs don’t just align better with fluctuating budgets. They also give you real time insight into asset health. That means you can:

- Defer maintenance on healthy equipment with confidence

- Increase frequency where failure risk is trending upward

- Make budget decisions based on risk, not guesswork.

In uncertain times, stable maintenance strategies are gold. And there’s nothing more stable than letting the machine tell you when it needs attention.

Worried about market conditions? Get advice from three manufacturing veterans on what you can control, and how to adjust accordingly.