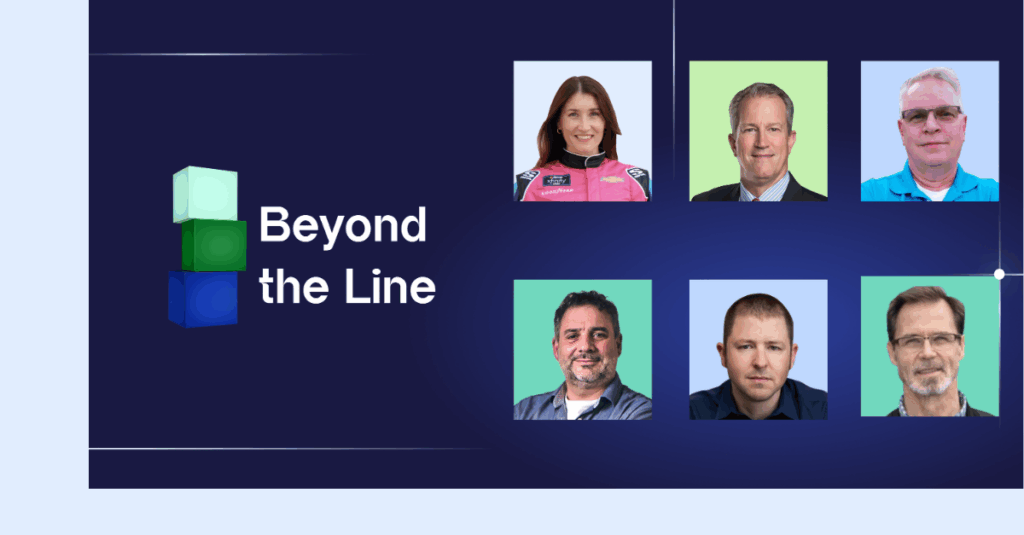

Beyond the Line 2025: From Firefighting to the Finish Line

What do NASCAR pit crews and manufacturers have in common? More than you'd think. Augury's Beyond the Line 2025 wasn't your typical industry event. It was an hour of conversations with manufacturing leaders and a special NASCAR guest. They shared real success stories and AI strategies that cracked the code on competitive advantage—and what you need to do to see the same results.