Utility equipment is essential in a production environment. Whether it’s a compressor or a chiller, their failure could lead to dramatic losses of revenue due to unplanned downtime. However, a predictive maintenance machine health program can cut back such losses by 99.9% – with a guarantee covering the remaining .1%. Curious? Watch the webinar now on-demand.

Utility Equipment Matters

Perhaps you’ve heard the story about Augury saving 960,000 beers just in time for Superbowl? More recently, a pharma customer avoided $1.1 million in downtime costs by preventing a failure in an air handling unit.

Our business is to make these stories happen. While utility equipment like AHAs and exhaust fans, chillers and compressors, boilers and heating systems often get less attention than critical production equipment, their failure can often prove to be very costly. But this no longer has to be the case.

Watch our on-demand webinar featuring Mike Roy, Vice President of Engineering at HSB and Artem Kroupenev, VP of Strategy at machine health specialists Augury to learn how to avoid, mitigate or even entirely cut those losses.

In This Webinar, You Will Learn:

- Why utility equipment matters in production environments

- Real-life claim costs from utility equipment failures

- How to avoid and mitigate the cost of utility equipment failures

- How Augury and HSB have partnered to offer the first insurance backed diagnostic offering

A Stellar Panel to Explain the Value of Machine Health

Our guests know what they are talking about. Artem Kroupenev is VP Strategy at Augury, where he oversees Augury’s AI-based machine health, performance, and digital transformation solutions. He has over a decade of experience in technology, product, innovation, and business development, and has co-founded technology companies in the U.S., Israel, and West Africa.

Meanwhile, The Hartford Steam Boiler Inspection and Insurance Company (HSB) was founded in 1866 and is a global specialty insurer and reinsurer and rates. Serving over five million commercial locations, the company rates as the largest provider of equipment breakdown insurance and related inspection services in North America. Michael Roy is the company’s VP of Engineering, where he leads the HSB Equipment Technology Lab which has a mission to identify, validate and demonstrate leading edge technologies. As such, he’s also the lead technical advisor for the Augury relationship within HSB.

In 2020, HSB backed a new warranty offering by Augury, which aims to minimize financial risk from industrial machine failures. The first of its kind, Guaranteed Diagnostics™ is a repair/replacement warranty that compensates customers in the very unlikely event of a missed diagnosis leading to equipment failure.

What Augury Learned at The Live Webinar:

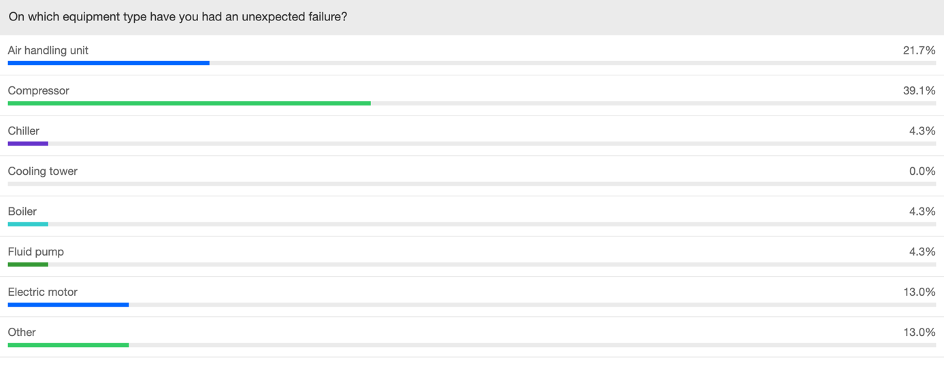

During the original live webinar in March 2021, we learned that 39% of attendees had experienced a compressor failure – with air handling units and electric motors following closely behind.

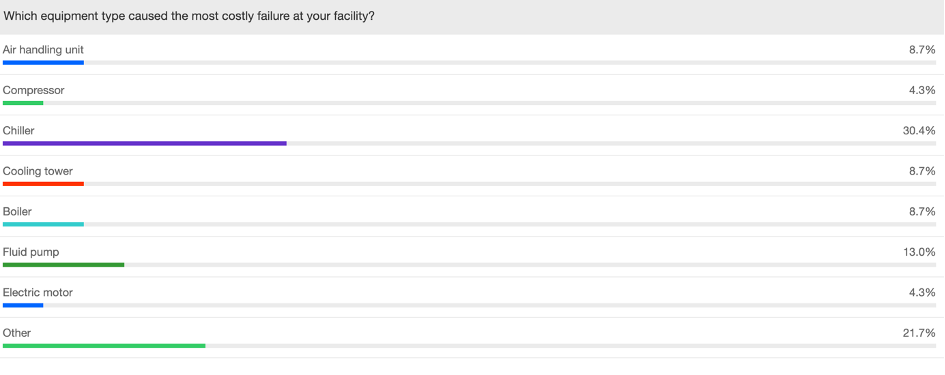

Meanwhile, 30% of attendees reported that a chiller caused the costliest utility equipment failure at their facility.

If you can relate to these issues in any way, you should sign up and watch the webinar – or reach out for a demo.